USPE manufactures a wide range of Gravity and Pressure/Gravity Fillers suitable for thin and flowable mildly viscous products. Time Gravity is an economical choice for beverages, cleaners, and thin products. This technique holds product in an elevated reservoir with a level monitoring system to produce a consistent head pressure. The fill volume is achieved by precision 1/100th second timer protocol that operates individual nozzle fill-valves. Gravity Fillers are used for plastic or complex containers. The time gravity technique is ideal choice for hazardous, corrosive product, or any product that low-pressure filling is required. Offered systems from Semi-Automatic 2-4 Head to Fully-Automatic 2-16 Head machines. Nozzle size from ¼” to 1-½”

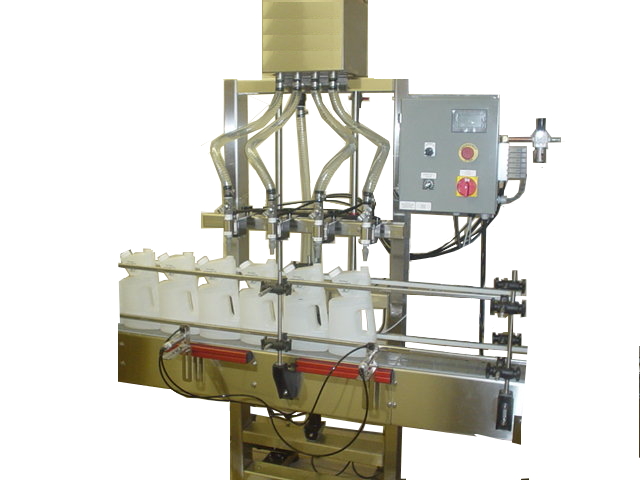

MODEL: FTG620-1

Automatic Time Gravity Filler

Fill system designed for low cost and high output packaging of thin liquids without particulates of solids. Commonly used for thin liquids like juices, cleaning chemicals, bleach, or acids. Constructed of 304 and 316 Stainless Steel and anodized aluminum. Options are available for all corrosive-resistant and hazardous location construction.

MODEL: FTG600-1 & FTG610-1

Semi-Automatic Time Gravity Filler

Fill system designed for low production. Accurate as the automatic gravity filler, but with manual bottle movement by an operator. Available with no air or electric pump system. Constructed of 304 and 316 Stainless Steel and anodized aluminum. Available in 2 or 4 Heads.